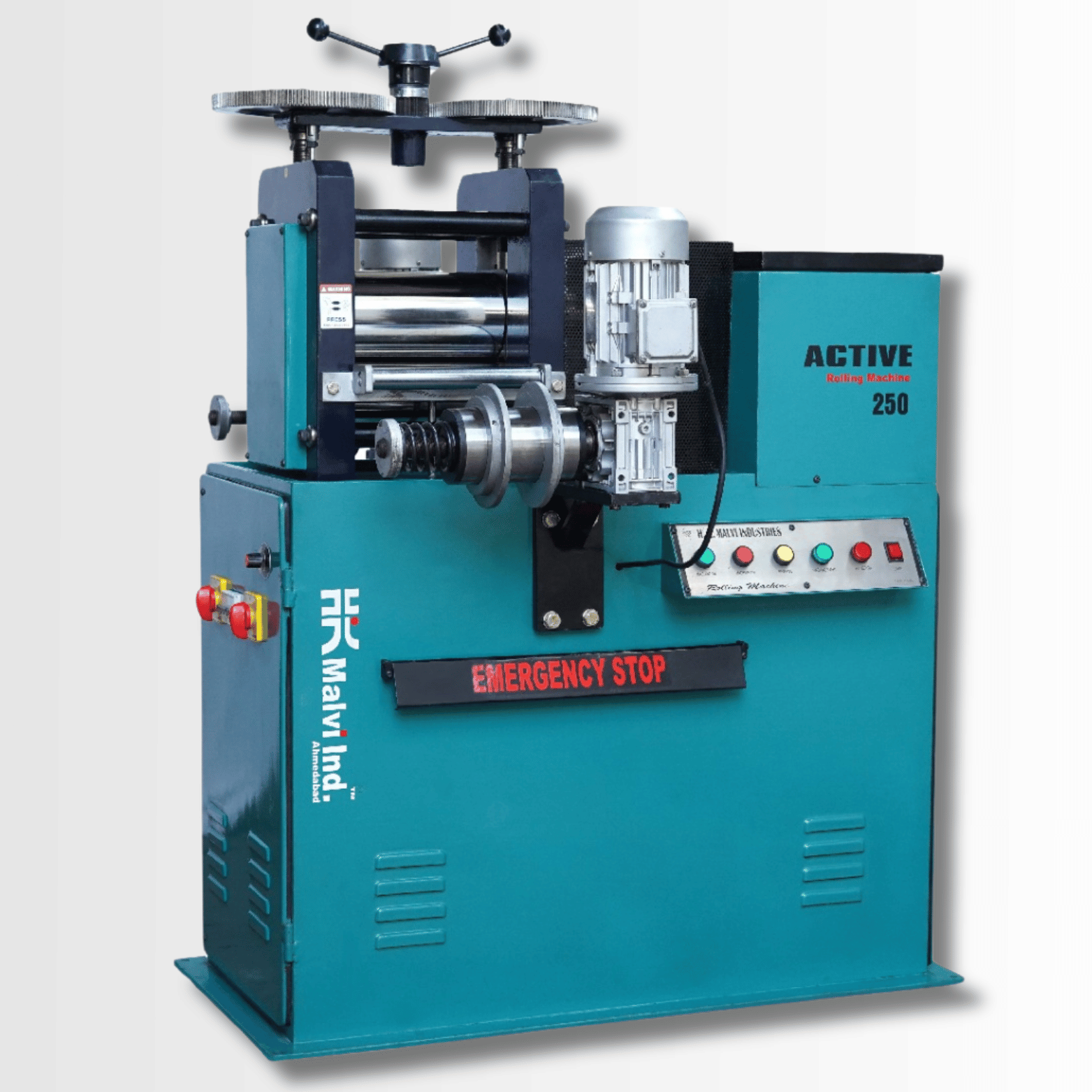

Single Head Gold Rolling Machine

- Home

- Single Head Gold Rolling Machine

Let’s Start Work

Together

Please feel free to contact us. We will get back to you with 1-2 business days. Or just call us now.

Download our document to see specific data of the service and how we work.

HK Malvi Industries – Jewellery Machine Manufacturer, Supplier And Exporter

At HK Malvi Industries, we are committed to delivering innovative, reliable, and high-performance solutions for the jewellery manufacturing industry. Our Single Head Gold Rolling Machine is engineered for precision, durability, and efficiency. With decades of experience, we have established ourselves as a Gold Jewellery Making Machine Manufacturer And Supplier in India, providing machinery that enhances productivity and ensures flawless results.

Leading Jewellery Machine Manufacturer, Supplier And Exporter in India

As a leading Jewellery Machine Manufacturer, Supplier And Exporter in India, HK Malvi Industries designs machines that simplify jewellery-making processes while ensuring accuracy and reliability. Our Single Head Gold Rolling Machine is ideal for rolling gold sheets and wires with uniform thickness, making it a valuable asset for both small workshops and large-scale production units.

Trusted Jewellery Machine Manufacturer, Supplier And Exporter in India

Being a Trusted Jewellery Machine Manufacturer, Supplier And Exporter in India, HK Malvi Industries focuses on quality, durability, and customer satisfaction. Each machine undergoes rigorous quality testing to guarantee smooth operation, minimal maintenance, and consistent performance, empowering jewellers to produce high-quality, flawless jewellery components every time.

Machine Description:

- ■ 5 Hp Three Phase Electric Motor

- ■ Gear Box System

- ■ Roller Metal- D2

- ■ Safty Guard – Optional

- ■ Standard Control Pannel

- ■ Branded Electrical Fittings

- ■ Standard Accessories

- ■ Heavy Duty Fabrication Structure

- ■ Machine Dimension

- ■ Machine Weight- 570 Kg

Machine Specification:

- ■ Sheet Size Inlet to Outlet- 15-0.1MM

- ■ No Noise & No Vibration

- ■ High Productivity

- ■ Warranty- 01 Year

Single Head Gold Rolling Machine Manufacturer, Supplier And Exporter in India

HK Malvi Industries stands as a leading Single Head Gold Rolling Machine Manufacturer, Supplier and Exporter in India, offering precision-engineered solutions trusted by jewellers worldwide. Our machines are designed to deliver uniform sheet and wire rolling, ensuring flawless finishing for bangles, rings, chains, and other intricate jewellery designs.

Single Head Gold Rolling Machine Manufacturer and Supplier in Ahmedabad

- ■ User-Friendly Operation: Designed with intuitive controls and a clear interface, our Single Head Gold Rolling Machine is remarkably easy to operate, even for those new to advanced machinery. Some models even feature a visual screen to monitor thickness in real-time, or PLC intelligent control for simplified parameter setting.

- ■ Robust and Durable Construction: Built with heavy-duty fabrication structures and thick materials, our machines are designed for continuous, 24-hour operation, ensuring stability and reliability for mass production needs.

- ■ Automatic Lubrication System (Optional/Integrated): Many of our models come equipped with an automatic oil supply system, eliminating the need for manual lubrication, enhancing safety, and preventing wear and tear on the rollers.

- ■ Adjustable Settings: Easily modify the roller gap to achieve a wide range of sheet and wire thicknesses, offering unparalleled versatility for diverse jewellery designs.

- ■ High Productivity: Engineered for high output, our machines significantly boost your production capacity while maintaining consistent quality.

- ■ Minimal Noise and Vibration: Designed for smooth and quiet operation, contributing to a more comfortable and productive working environment.

- ■ Safety Features: Integrated safety mechanisms are a priority, ensuring operator well-being during all stages of operation.

- ■ Versatile Applications: While optimized for gold, our machines are also suitable for rolling other precious metals like silver, copper, and platinum, expanding your production capabilities. Some machines even offer automatic winding devices with adjustable tension, further freeing up operators for other tasks.

Why Choose HK Malvi Industries ?

The applications of our Single Head Gold Rolling Machine are extensive within the jewellery industry:

- ■ Sheet Preparation: Creating perfectly flat and uniformly thick gold sheets for stamping, cutting, and shaping into various jewellery components like pendants, earrings, and bracelet links.

- ■ Wire Production: Producing gold wires of specific gauges and profiles for intricate designs, chain making, and wire-wrapping techniques.

- ■ Texturing: With appropriate rollers, our machines can also be used to impart unique textures and patterns onto gold surfaces, adding an artistic dimension to your creations.

- ■ Recycling and Reuse: Efficiently rolling down scrap gold for melting and reuse, minimizing waste and maximizing profitability.

- ■ Component Manufacturing: Producing components for a wide array of jewellery items, including rings, necklaces, bracelets, and earrings, with consistent quality.

Jewellery Machine Manufactured with Excellence: Our Commitment

Every Jewellery Machine Manufactured by HK Malvi Industries undergoes rigorous quality checks and adheres to stringent international standards. We believe that a superior machine is not just about its features but also about its longevity, reliability, and the support that comes with it. Our manufacturing processes are designed for precision, ensuring that each component is perfectly crafted and assembled. From the selection of high-quality materials to the final testing, every step is meticulously controlled to deliver a machine that you can trust for years to come.

Global Reach with Jewellery Machinery Excellence

As a leading Jewellery Machine Exporter in India, HK Malvi Industries supplies advanced and reliable machines to global markets. We proudly export to Dubai, Kuwait, Bangladesh, Saudi Arabia, Qatar, Australia, New Zealand, USA, Oman, Brazil, Colombia, Peru, Russia, Canada, Italy, and South Africa, supporting jewellers worldwide with trusted machinery solutions.

Maintenance and Care for Your Single Head Gold Rolling Machine

To ensure the longevity and optimal performance of your Single Head Gold Rolling Machine, regular maintenance is essential. We provide comprehensive guidelines with every machine, and our support team is always available for assistance. Key maintenance practices include:

- ■ Regular Cleaning and Lubrication: Keeping the machine free from metal shavings and debris, and applying recommended lubricants to moving parts, gears, and bearings.

- ■ Roller Inspection and Adjustment: Regularly checking rollers for wear, cracks, or damage, and ensuring proper alignment to prevent uneven rolling and maximize the lifespan of the rollers.

- ■ Fastener Monitoring: Periodically checking and tightening all bolts and screws to maintain machine stability and prevent malfunctions.

- ■ Electrical Component Checks: Inspecting wiring and connections for wear or damage to prevent electrical failures and ensure safety.

- ■ Professional Inspections: Scheduling periodic comprehensive inspections by qualified technicians to ensure all systems are functioning optimally.

FAQs: Single Head Gold Rolling Machine

1: What is the production capacity of the Single Head Gold Rolling Machine?

Depending on model specifications, our machines can roll 0.1 mm to 5 mm thick gold sheets at speeds of up to 30 RPM.

2: Is operator training provided?

Yes, we offer both on-site and remote training for your staff to operate the machine efficiently and safely.

3: Can this machine be used for silver and other metals?

Absolutely. It’s suitable for silver, platinum, and various precious and semi-precious metals.

4: How often does it require maintenance?

Minimal maintenance is needed. Basic checks once a month and lubrication every 3 months are recommended.

5: Can I request a custom machine size or specification?

Yes. We offer customization based on roller diameter, length, and motor capacity as per your production requirements.

Get in Touch with HK Malvi Industries Today

Elevate your jewellery manufacturing capabilities with the Single Head Gold Rolling Machine from HK Malvi Industries—India’s most trusted jewellery machine manufacturer. From impeccable engineering to reliable after-sales support, we ensure you stay ahead in today’s competitive jewellery market.