Gold Laser Cutting – Compact

- Home

- Gold Laser Cutting – Compact

Let’s Start Work

Together

Please feel free to contact us. We will get back to you with 1-2 business days. Or just call us now.

Download our document to see specific data of the service and how we work.

The Future is Compact: Revolutionizing Gold Jewellery Manufacturing with Advanced Laser Cutting

The Indian jewellery sector is swiftly embracing technology to keep pace with the increasing demand, both domestically and globally. At the heart of this evolution is laser cutting, along with advanced Gold Jewellery Making Machines.

As we shift from the picturesque lanes of traditional goldsmithing towns to lively manufacturing centers, a growing number of jewellers are turning to Jewellery Machines built with laser precision. This shift allows them to produce exquisite collections that genuinely connect with modern buyers.

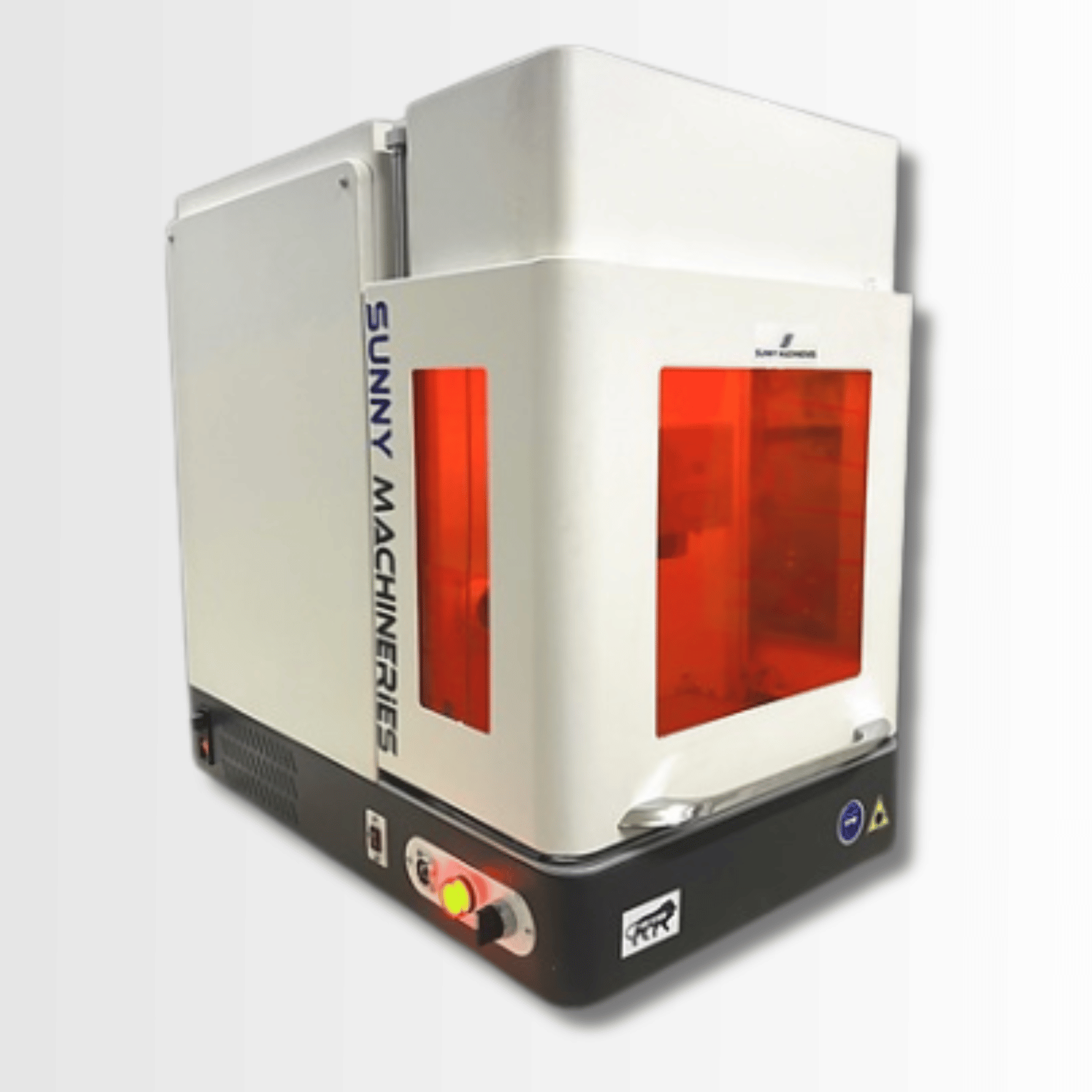

Why Gold Laser Cutting – Compact Is the Future of Jewellery Manufacturing

Gold laser cutting machines used to be bulky and space-consuming. With the compact version, even small workshops can now leverage cutting-edge technology without compromising on performance. These machines offer:

- ■ Precision cutting with micrometer-level accuracy

- ■ Faster turnaround with automated controls

- ■ Energy-efficient operation for sustainable production

This innovation is driving the future of Gold Jewellery Making Machine technology in India and beyond.

HK Malvi Industries: A Trusted Jewellery Machine Manufacturer in India

When it comes to sourcing reliable, high-performance equipment, HK Malvi Industries has set a benchmark in the industry. As a premier Jewellery Machine Manufacturer, the company specializes in delivering:

- ■ Durable and robust machinery for long-term use

- ■ Technical innovation tailored to Indian and international markets

- ■ Complete customer support, from installation to training

HK Malvi Industries is more than just a Jewellery Machine Manufacturer in India – it’s a brand that upholds craftsmanship and innovation.

Applications of Gold Laser Cutting: Compact in Jewellery Making Machines

1. Intricate Design Cutting

The precision of compact laser cutting enables artisans to execute the most delicate and intricate patterns on gold sheets, essential for rings, pendants, earrings, and designer bangles.

2. Custom Engraving

Advanced laser modules allow for accurate engraving of personalized designs, names, or logos – a growing trend in custom jewellery offerings.

3. Micro-Component Fabrication

Modern jewellery often includes tiny, detailed components. Compact laser machines are perfect for manufacturing these with tight tolerances and repeatable accuracy.

Features of Modern Gold Jewellery Making Machines with Laser Cutting

The Gold Laser Cutting – Compact systems now come loaded with features that significantly enhance production quality:

- ■ High-Speed Operation: Equipped with advanced galvanometer systems and fiber laser technology, these machines cut at speeds of up to 10000 mm/s without compromising accuracy.

- ■ Automatic Focus Adjustment: The auto-focus feature helps maintain consistent beam quality across various gold thicknesses, ensuring minimal waste and improved finish.

- ■ User-Friendly Interface: Most modern systems come with touchscreen interfaces and design software compatibility, making them easy to use even for beginners.

- ■ Compact Design: The small footprint makes these machines ideal for space-constrained environments without compromising performance.

Benefits of Using Compact Gold Laser Cutting Machines

- ■ Precision and Consistency: Laser cutting ensures zero deviation in repetitive jobs, making it ideal for mass production. This reliability is essential for any Gold Jewellery Making Machine operation.

- ■ Reduced Material Wastage: Traditional cutting methods often lead to material loss. Laser cutting ensures clean cuts and better utilization of gold sheets.

- ■ Time Efficiency: Faster cutting speeds reduce turnaround time and boost production capacity – a crucial factor in today’s competitive market.

- ■ Cost Savings: Lower energy consumption, minimal gold wastage, and reduced manpower make Gold Laser Cutting – Compact an economically viable solution for jewellery makers.

Jewellery Machine Manufactured with Innovation and Reliability

At HK Malvi Industries, every jewellery machine is put through rigorous quality control and testing to ensure top-notch performance. The company is all about innovation, keeping pace with the ever-changing trends in jewellery design and production.

Their Gold Jewellery Making Machines, particularly the compact laser cutting models, are designed to be future-ready. They incorporate IoT and smart manufacturing concepts, helping jewellers stay ahead of the game.

Why Choose a Jewellery Machine Manufacturer in India?

Choosing a Jewellery Machine Manufacturer in India offers multiple benefits:

- ■ Localized Support: Immediate technical assistance and spare parts availability.

- ■ Affordability: World-class machinery at competitive pricing.

- ■ Cultural Understanding: Machines designed with Indian jewellery trends and traditions in mind.

- ■ Export Readiness: Indian manufacturers like HK Malvi Industries also cater to global standards, ensuring international compatibility.

Industries and Professionals Benefiting from Gold Laser Cutting – Compact

- ■ Retail Jewellers: Boutique stores use compact machines for personalized jewellery and small-batch production.

- ■ Large-Scale Manufacturers: Mass producers rely on laser precision for uniformity and speed.

- ■ Jewellery Designers: Artists and CAD designers use laser cutting to bring their digital creations to life with exceptional detail.

- ■ Training Institutes: Jewellery design and manufacturing schools use compact laser cutters as part of their curriculum to familiarize students with modern techniques.

Customization with Gold Laser Cutting

The future of Gold Jewellery Making Machines lies in customization. Gold laser cutters offer:

- ■ Layered texture designs

- ■ 3D engraved effects

- ■ Fine stencil creations

- ■ Mixed material compatibility (for combining gold with silver, copper, etc.)

This opens new creative possibilities for designers and enables them to cater to a more diverse clientele.

Eco-Friendly Jewellery Manufacturing

As sustainability becomes a major concern in all industries, Gold Laser Cutting – Compact machines align perfectly with eco-friendly manufacturing goals:

- ■ Minimal emissions

- ■ Lower energy consumption

- ■ Precise cutting reduces gold waste

- ■ Cleaner production environments

This makes them the go-to option for manufacturers looking to reduce their environmental impact without compromising on quality.

Maximize output, minimize waste—contact HK Malvi Industries for next-gen Gold Jewellery Making Machines with compact laser cutting power.