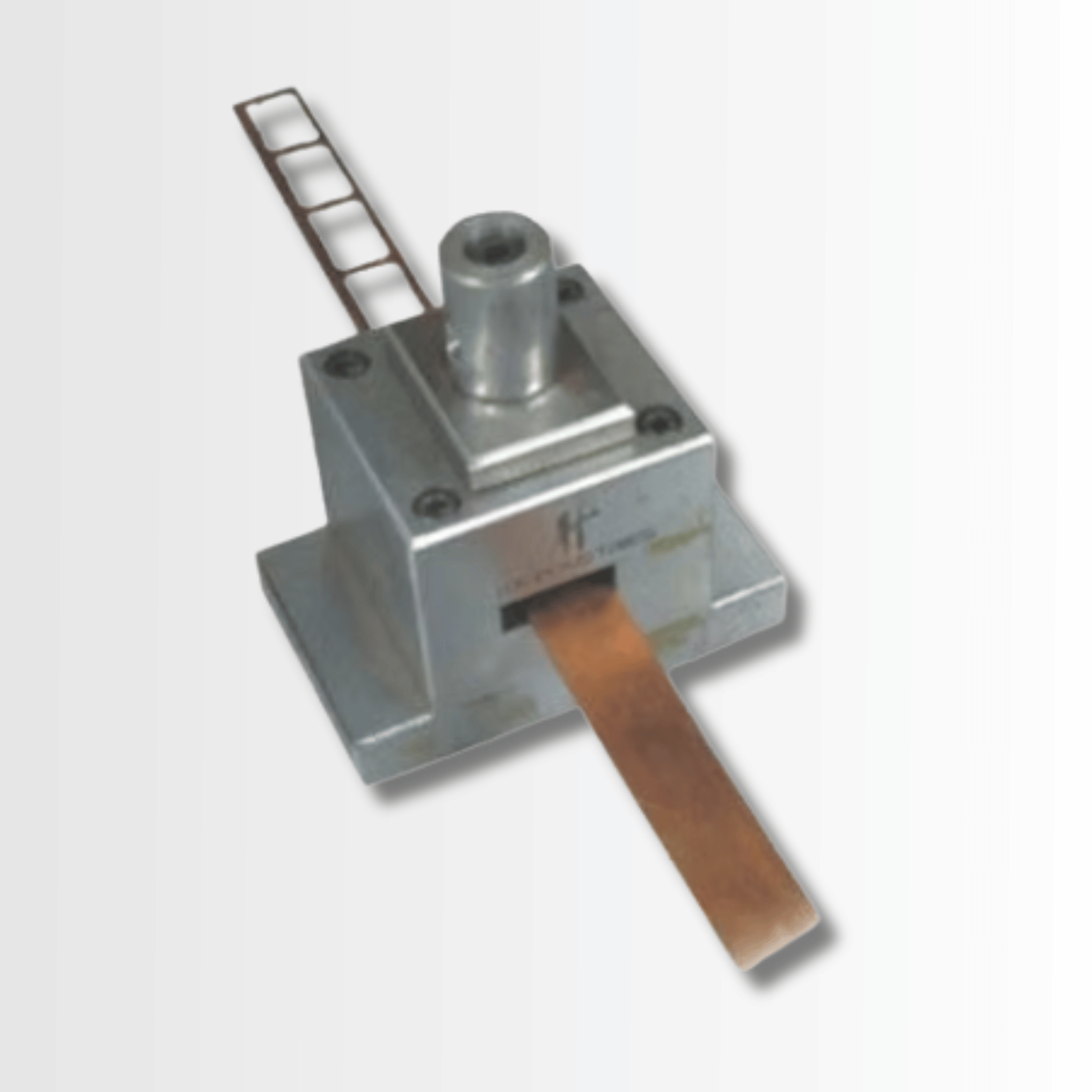

Blanking Cutting Die

- Home

- Blanking Cutting Die

Let’s Start Work

Together

Please feel free to contact us. We will get back to you with 1-2 business days. Or just call us now.

Download our document to see specific data of the service and how we work.

Gold Jewellery Making with Precision Blanking Cutting Dies: A Deep Dive for Modern Jewellers

In the world of Gold Jewellery Making Machines, having the right precision tools is crucial for perfect craftsmanship. The Blanking Cutting Die is one such tool that stands out, offering remarkable accuracy, efficiency, and consistency in jewellery design. It’s a favourite among industry leaders like HK Malvi Industries, a well-known Jewellery Machine Manufacturer in India, and plays a key role in the jewellery production process.

This blog will take you through everything you should know about blanking cutting dies, their significance in gold jewellery manufacturing, and the importance of choosing a trusted Jewellery Machine Manufacturer for your success.

What is a Blanking Cutting Die?

A Blanking Cutting Die is a specialized tool that cuts flat pieces of metal—referred to as blanks—from a sheet. These blanks are essential for crafting detailed jewellery designs, including pendants, earrings, bangles, and beyond.

What sets blanking cutting dies apart from general-purpose dies is their high precision, ensuring that each cut is not only clean and uniform but also free of rough edges. This kind of consistency is particularly important in high-volume production environments, which are often found in Gold Jewellery Making Machines.

Importance of Blanking Cutting Die in Gold Jewellery Making Machines

- ■Gold Jewellery Making Machines

- ■Coin & Bar Moulding Machines

- ■Precision cutting in jewellery making

- ■High-volume production for various industries

Our Blanking Cutting Dies are manufactured using advanced technology, ensuring that each die has high wear resistance and durability. This guarantees that your gold jewellery making machines continue operating at optimal performance for years.

High-Quality Jewellery Manufacturing Machines

- ■ Precision Craftsmanship: Gold is a delicate and expensive metal, so there’s zero room for error. Blanking cutting dies ensure the dimensions of each jewellery component are exact, reducing wastage and improving output quality.

- ■ High-Speed Production: Modern Gold Jewellery Making Machines integrated with blanking cutting dies can produce thousands of blanks per hour. This level of speed and consistency is vital for jewellery manufacturers looking to scale their operations.

- ■ Compatibility with Various Metals: Although primarily used for gold, blanking cutting dies can also be used for silver, platinum, and other precious metals, making them a versatile asset in any Jewellery Making Machine setup.

Why Choose HK Malvi Industries for Blanking Cutting Dies?

When it comes to Jewellery Machine Manufactured in India, HK Malvi Industries is a name that resonates with quality, reliability, and innovation. Here’s why they are the preferred Jewellery Machine Manufacturer in India:

- ■ Precision Engineering: HK Malvi Industries uses state-of-the-art CNC and laser technology to manufacture blanking cutting dies that meet the most stringent tolerances.

- ■ Custom Die Design: From floral motifs to geometric patterns, HK Malvi offers fully customizable dies based on client requirements, ensuring artistic freedom in gold jewellery making.

- ■ Durable Materials: Made from high-grade tool steel and heat-treated for durability, HK Malvi’s blanking cutting dies offer extended service life, reducing the need for frequent replacements.

- ■ After-Sales Support: Their unmatched customer service ensures technical guidance, maintenance support, and prompt issue resolution, making them a trusted Jewellery Machine Manufacturer.

Features of a High-Quality Blanking Cutting Die

Choosing the right Blanking Cutting Die involves understanding the key features that define its performance and durability:

- ■ Razor-Sharp: Ensures a clean, burr-free cut that minimizes post-processing work.

- ■ Tight Tolerances: Maintains dimensional accuracy across thousands of cycles, which is essential for mass production.

- ■ Interchangeable Inserts: Some dies come with interchangeable parts that allow quick pattern changes, improving operational flexibility.

- ■ Corrosion Resistance: Coated surfaces prevent oxidation, especially important when working with precious metals like gold.

Applications in Gold Jewellery Making Machines

- ■ Blanking for Earrings and Pendants: The die cuts out base shapes used to create intricate designs in earrings and pendants.

- ■ Bangle Strip Cutting: Strips used in bangle formation can be pre-cut using blanking dies, saving time and ensuring uniformity.

- ■ Ring Base Cutting: Perfectly shaped ring bases can be produced in bulk with minimal material loss.

- ■ Customized Design Production: Designers can create unique patterns by commissioning custom blanking cutting dies for signature collections.

How Blanking Cutting Dies Enhance Production Efficiency

Incorporating blanking cutting dies in Gold Jewellery Making Machines leads to tangible operational benefits:

- ■ Reduced Production Time: Automation reduces manual labour and accelerates output.

- ■ Lower Material Wastage: Accurate cutting minimizes gold loss, which is crucial given the cost of raw materials.

- ■ Consistent Quality: Identical pieces ensure symmetry in final jewellery, enhancing visual appeal and customer satisfaction.

Integration with Other Jewellery Making Machines

A Blanking Cutting Die doesn’t work in isolation—it’s often integrated with other machinery in a Gold Jewellery Making Machine production line, such as:

- ■ Hydraulic Press Machines: Used to apply the necessary force for die cutting.

- ■ Forming Machines: Once the blank is cut, it is shaped into the desired jewellery form.

- ■ Laser Engraving Machines: Add fine details and customization post-blanking.

This interconnected workflow streamlines the entire jewellery manufacturing process, and ensures that every component from blank to finished product is top-tier.

Choosing the Right Jewellery Machine Manufacturer in India

HK Malvi Industries in India is a hub for gold jewellery production, and finding the right Jewellery Machine Manufacturer can make all the difference in your production quality and business growth.

When choosing a manufacturer, consider:

- ■ Proven industry experience.

- ■ Precision manufacturing capabilities.

- ■ Ability to offer custom solutions.

- ■ Reliable after-sales service.

- ■ Use of advanced technology in machine production.

Blanking Cutting Die: The Heart of Modern Jewellery Making

As the demand for intricate and luxurious jewellery continues to rise, the need for efficient and precise manufacturing tools like the Blanking Cutting Die has never been more crucial. When combined with modern Gold Jewellery Making Machines, this die truly becomes the lifeblood of any thriving jewellery workshop.

By collaborating with industry leaders such as HK Malvi Industries, you not only gain access to the finest Jewellery Machines manufactured in India but also position your business to stay ahead in design, speed, and precision.

Contact Us for HK Malvi Industries

Are you ready to upgrade your jewellery manufacturing process with high-precision Blanking Cutting Dies and Gold Jewellery Making Machines?

At HK Malvi Industries, a trusted Jewellery Machine Manufacturer in India, we’re here to help you streamline production, reduce waste, and deliver unmatched design precision.