Tube Extrusion Machine

- Home

- Tube Extrusion Machine

Let’s Start Work

Together

Please feel free to contact us. We will get back to you with 1-2 business days. Or just call us now.

Download our document to see specific data of the service and how we work.

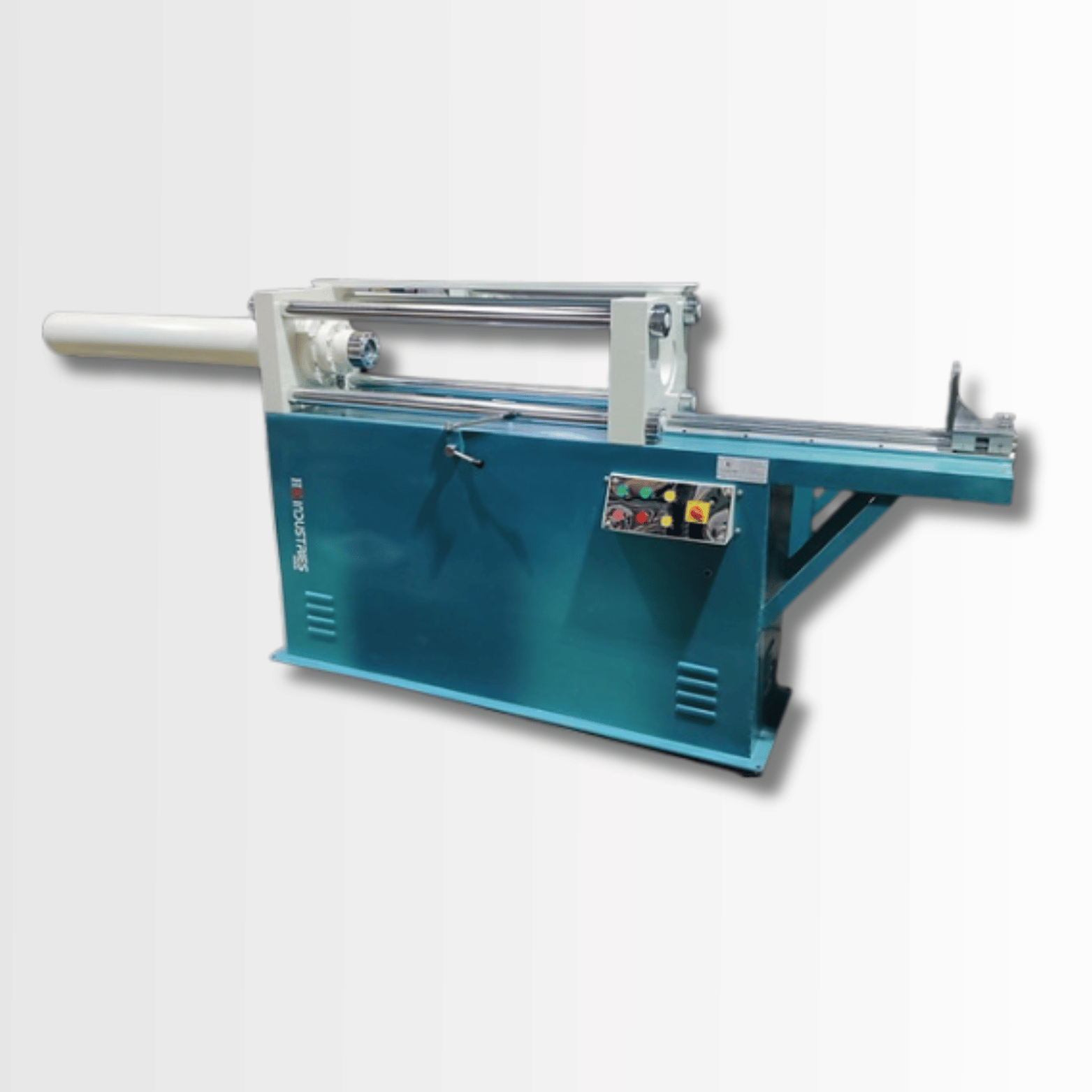

Tube Extrusion Machine: A Crucial Component in Gold Jewellery Making Machines

When it comes to making exquisite gold jewellery, you can’t overlook the importance of precision, consistency, and high-quality manufacturing tools. The Tube Extrusion Machine is one of those essential tools, playing a key role in creating seamless gold tubes that form the basis for rings, bangles, beads, and other fine items. As the desire for quality jewellery increases, the need for advanced Gold Jewellery Making Machines like the tube extrusion machine has become increasingly vital.

HK Malvi Industries: Leading Jewellery Machine Manufacturer in India

HK Malvi Industries has made quite a name for itself in the Indian jewellery machinery manufacturing scene. As a leading Jewellery Machine Manufacturer, they’re well-known for crafting high-performance equipment that keeps up with the ever-changing needs of today’s goldsmiths. With years of experience under their belt and a strong focus on innovation, HK Malvi Industries has become the go-to place for Gold Jewellery Making Machines, including the latest in Tube Extrusion Machines.

By consistently upgrading their manufacturing technology and adhering to international quality standards, they’ve established themselves as one of the top Jewellery Machine Manufacturers in India.

What is a Tube Extrusion Machine?

A Tube Extrusion Machine is a specialized piece of equipment used to form seamless metal tubes from precious metals like gold and silver. In the context of jewellery manufacturing, this machine extrudes gold billets into long, cylindrical tubes of uniform thickness and diameter. These tubes are then cut, shaped, or refined into components like bangles, rings, and chains.

This process is essential for producing high-quality tubes with smooth finishes, precise dimensions, and optimal material integrity – qualities that are critical in fine jewellery production.

Role of Tube Extrusion in Gold Jewellery Making Machines

Tube extrusion is more than just a forming process; it’s the backbone of efficient, high-volume, and precision-based jewellery production. When integrated with other Jewellery Making Machine systems, tube extrusion machines provide the following advantages:

1. Seamless Tube Formation

Unlike older methods that involved rolling and welding, tube extrusion produces a seamless tube, resulting in higher strength and better aesthetic appeal. For delicate gold jewellery, seamless construction is critical.

2. Uniformity in Dimensions

Consistency is key in jewellery manufacturing. The tube extrusion machine ensures that the tubes have uniform thickness and diameter throughout their length, reducing waste and increasing quality.

3. Increased Production Efficiency

Automated tube extrusion allows jewellery manufacturers to increase their production speed without compromising on quality. This efficiency is vital for businesses scaling operations or fulfilling large orders.

4. Supports Diverse Designs

Extruded gold tubes can be further processed into a wide variety of designs. From classic bangles to intricate rings, the machine’s versatility supports a broad range of jewellery types.

Features of High-Quality Tube Extrusion Machines

When choosing a Tube Extrusion Machine for your gold jewellery manufacturing line, certain features can make a significant difference in output quality and reliability.

- ■ High Precision Die Assembly: Quality extrusion depends on precision dies. The machine must have high-precision die holders to ensure uniform flow of gold without surface imperfections.

- ■ Temperature Control: Since gold becomes malleable at high temperatures, optimal heating control ensures better extrusion and reduced material loss.

- ■ Strong Hydraulic Press: A powerful hydraulic system provides the necessary pressure to extrude gold billets into tubes. Machines from leading brands like HK Malvi Industries include advanced hydraulic technology for smooth operation.

- ■ Easy Maintenance: Downtime is costly. Tube extrusion machines should be built with easy-access components, allowing for fast maintenance and reduced operational interruptions.

- ■ Safety Mechanisms: High-grade safety features ensure the protection of both operators and the material being processed, especially when dealing with expensive metals like gold.

Applications of Tube Extrusion Machines in Gold Jewellery Making

- ■ Bangle Tubes: Thick and wide tubes formed for bangles.

- ■ Chain Tubes: Thin and lightweight tubes used in chains and necklaces.

- ■ Ring Blanks: Tubes that are later cut and shaped into rings.

- ■ Beads and Pendants: Hollow tubes cut and crafted into decorative beads or pendant elements.

Why HK Malvi Industries is the Best Choice for Jewellery Making Machine

- ■ Extensive Experience: With years of industry experience, HK Malvi Industries has mastered the art of developing machines that meet the exacting standards of modern jewellery manufacturers.

- ■ End-to-End Solutions: From gold melting machines to final polishing units, they provide a full range of Gold Jewellery Making Machines, including Tube Extrusion Machines.

- ■ Customization Available: Every jewellery business is different. HK Malvi offers tailored machinery solutions to fit your specific production needs.

- ■ Quality Assured: As a trusted Jewellery Machine Manufacturer in India, HK Malvi adheres to international quality benchmarks ensuring every machine is built to last and deliver.

- ■ Affordable Pricing: While quality is paramount, HK Malvi also ensures their machines are competitively priced – making high-end manufacturing accessible even for small workshops.

Jewellery Machine Manufactured with Precision and Excellence

At HK Malvi Industries, excellence is a given when it comes to their Jewellery Machines. Every piece, including the Tube Extrusion Machine, is made with technology, thorough quality inspections, and exceptional engineering. These machines are built for long-lasting performance and improved productivity, allowing businesses to effortlessly craft beautiful jewellery that lasts.

Benefits of Using Tube Extrusion Machines in Your Jewellery Workshop

- ■ Boost Productivity: Extrude gold tubes faster and more efficiently than manual methods.

- ■ Enhance Quality: Achieve smoother, defect-free tubes that reflect in the final product.

- ■ Reduce Material Wastage: Precision engineering means you use exactly what you need, minimizing gold loss.

- ■ Elevate Craftsmanship: Provide your artisans with quality base materials to unleash their creativity.

Why Gold Jewellery Making Machines Are Evolving

The global jewellery market is more competitive than ever. From traditional Indian designs to contemporary global trends, manufacturers are under pressure to deliver precision, speed, and creativity. That’s why Gold Jewellery Making Machines like tube extrusion machines are evolving with automation, smart controls, and hybrid integration.

Modern machines offer better digital interfaces, improved power efficiency, and lower maintenance – transforming the way jewellery is made.

Ready to Upgrade Your Jewellery Manufacturing Process?

Contact HK Malvi Industries today and explore their complete range of Jewellery Making Machine solutions – including high-performance Tube Extrusion Machines tailored for your business.