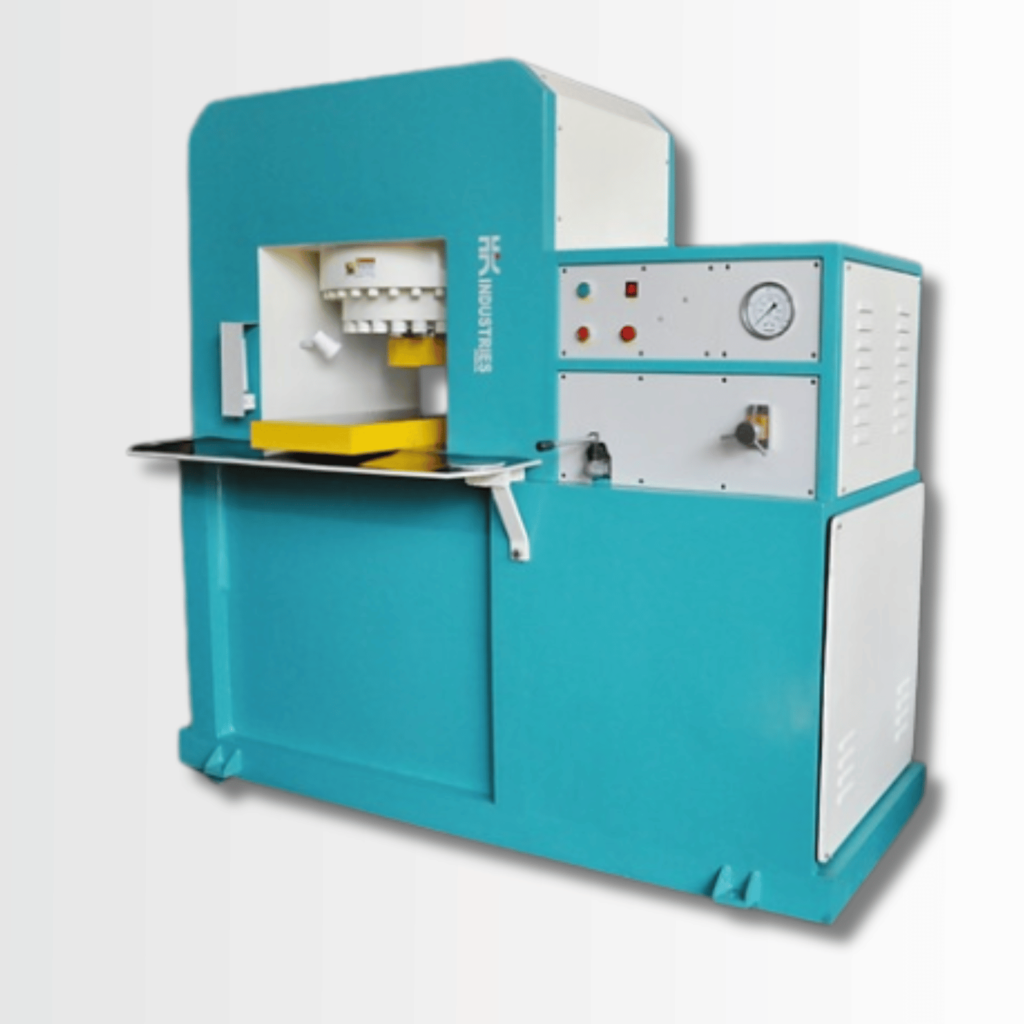

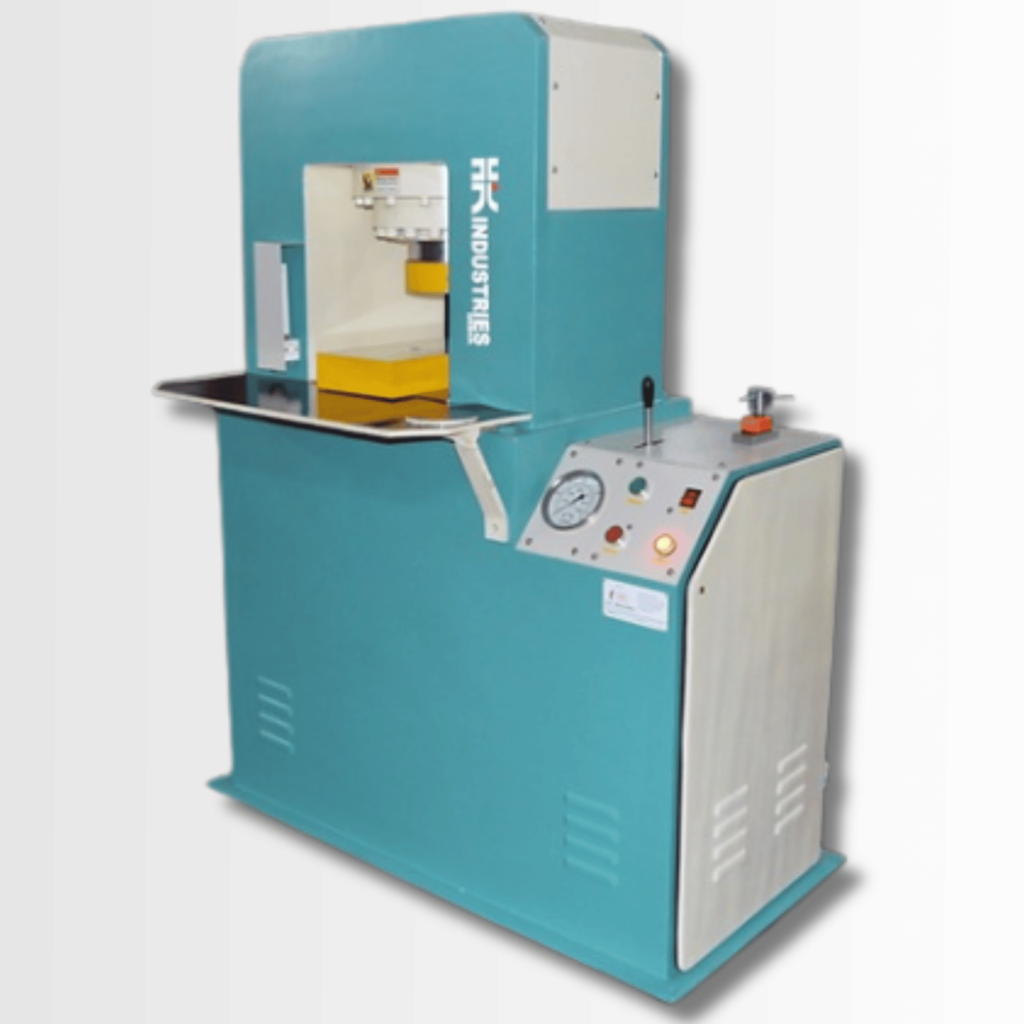

Hydraulic Press Machines for Gold/Silver Coins & Bars

These machines ensure precise and high-quality production of gold/silver coins and bars, with advanced PLC controls, high embossing forces, and options for automatic or manual operation.

- Home

- Hydraulic Press Machines for Gold/Silver Coins & Bars

A hydraulic press machine is a type of machine that uses hydraulic force to perform a variety of operations, including shaping, molding, and forming materials, as well as pressing and compressing materials to achieve a desired shape or size. The core principle of a hydraulic press involves using a liquid (usually oil) to generate force through a hydraulic system.

A hydraulic press machine is a specialized piece of equipment that utilizes hydraulic force to perform a wide range of tasks, including shaping, molding, and forming materials, as well as compressing or pressing them to achieve specific dimensions or shapes. This is achieved by using a liquid (typically oil) to generate force within the hydraulic system.

Various types of hydraulic press machines cater to specific needs, including:

- Hydraulic Auto Minting Press: Designed for automatic coin minting, offering high efficiency and precision.

- Hydraulic Auto/Manual Minting Press (Heavy Duty Series): A versatile press that allows for both automatic and manual operation, built to handle heavy-duty minting tasks.

- Hydraulic Manual Minting Press: A press that requires manual operation for minting coins, ideal for low-volume production.

- Hydraulic Coin Blanking Press: Used specifically for blanking coin discs from metal sheets, a key step in coin manufacturing.

- High-Speed Die Cutting Machine: A hydraulic machine that rapidly cuts materials with high precision, ideal for high-volume production.

- Hydraulic Stamping & Cutting Press Multipurpose: A versatile machine used for both stamping and cutting various materials, offering flexibility for different applications.

- Hydraulic Stamping Press: Specialized for stamping metal sheets into various shapes, commonly used in coin and component manufacturing.

- Coin Rimming Machine: A machine designed to apply a rim or edge to minted coins, adding a finished and detailed touch to the coin.

- Dot Pin Marking Machine: A marking machine that uses dot peen technology to etch or mark parts with high precision.

- Tube Extrusion Machine: Used to produce tubes and profiles by forcing heated material through a mold, often used in metal and plastic processing.

These hydraulic press machines are essential in industries like coin minting, metalworking, and component manufacturing, offering precision, efficiency, and versatility in a range of applications.