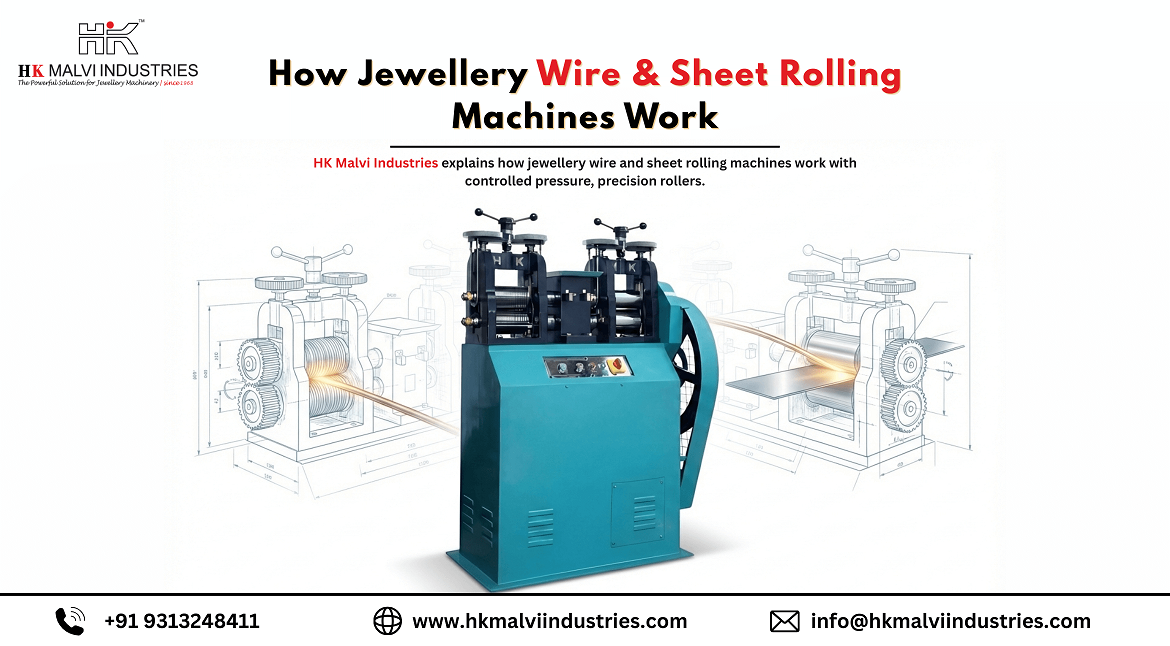

HK Malvi Industries: Understanding the Working of Jewellery Wire & Sheet Rolling Machines

Gold jewellery manufacturing has changed significantly over the last two decades. What was once a largely artisan-driven process is now a carefully balanced combination of skill, process control, and reliable machinery. As jewellery markets expanded beyond local boundaries, manufacturers in India, the Middle East, Europe, and Western countries began facing similar challenges—maintaining precision, reducing gold loss, managing skilled labor shortages, and meeting strict export quality standards. How Jewellery Wire & Sheet Rolling Machines work plays a key role in addressing these challenges, ensuring accurate metal shaping, consistent thickness, and efficient production for modern jewellery manufacturing.

In export-focused jewellery making, consistency is no longer optional. Purchasers in markets such as the UAE, Europe, and North America anticipate uniform gauge, reliable weight, and repeatable surface treatment on every production run. This is where the Jewellery Wire Sheet Rolling Machine has emerged as a practical, daily aid in workshops and production facilities worldwide, helping producers maintain control without sacrificing artisan skill.

Evolving Demands of Contemporary Jewellery Production

Today’s jewellery makers operate within a highly integrated global supply chain. Increased export orders necessitate faster completion times and tighter parameters. International quality benchmarks demand uniformity not just in design but also in material distribution and finish.

Workshops in India, the UAE, the USA, and Europe frequently encounter similar pressures:

- Sustaining uniformity from batch to batch

- Lowering reliance on highly specialized manual proficiencies

- Managing efficiency in time and expense

Seasoned global jewellery manufacturers often confront these shared hurdles, irrespective of location. Equipment that introduces predictability into daily output has become vital.

What Is a Jewellery Wire Sheet Rolling Machine?

In basic workshop vernacular, a Jewellery Wire Sheet Rolling Machine serves to diminish and regulate the thickness of gold by passing it between hardened cylinders. Rather than relying solely on manual striking or repeated hand-rolling, the apparatus permits slow, controlled reduction.

In international workshop settings, this apparatus is generally placed between casting and shaping segments. It helps transform raw cast ingots into level sheets or wires that are simpler to shape, bond, and perfect—without straining the metal or the technician.

Why Jewellery Wire Sheet Rolling Machine Is Superseding Conventional / Manual Techniques Globally?

Older rolling processes rely heavily on individual competency levels. While artistry remains important, manual variance often leads to uneven thickness and higher rejection rates.

Machine-based workflows provide:

- Decreased reliance on artisan skill discrepancies

- Consistent quality appropriate for export destinations

- Greater oversight of material volume and gauge

For producers catering to a global clientele, this transition enhances predictability without eliminating the human element in final design phases.

Gains in Output & Excellence in Routine Tasks

In day-to-day manufacturing, even slight improvements are significant. Producers across India and export-centric regions note smoother operations when rolling is standardized.

Advantages often noted include:

- Quicker output without hurrying operators

- Consistent design quality across different shifts

- Stable functionality even during extended production hours

- Uniformity at this stage simplifies subsequent procedures, such as forming and buffing.

Decreasing Gold Waste & Supervising Expenses

Controlling gold wastage is crucial everywhere, but especially in tight-budget markets like India and trade centers in the Middle East. Western export units also emphasize waste management to sustain competitive pricing.

Practical illustrations involve:

- Less edge cutting is needed due to even thickness

- Fewer corrections resulting from uneven rolling

- Better weight accuracy for shipping documents

These are process-level enhancements that accumulate over time, rather than mere assertions.

Simplicity of Use, Operator Comfort & Facility Safety

Modern rolling apparatuses are engineered for safer handling and smoother operation. In facilities employing diverse workforces, ease of operation becomes a factor.

Key elements encompass:

- Diminished technician strain during extended work periods

- Safer management of hot or partially processed gold

- Simple controls adaptable to varied ability levels

These elements contribute to steady output and reduced operational tension.

Technology, Accuracy & Operational Dependability

From a technical viewpoint, dependability outweighs complexity. Manufacturers supplying international buyers frequently undergo assessments concentrating on process stability.

Simple mechanical accuracy, steady roller alignment, and dependable power provisions guarantee:

- Uniform outcomes across manufacturing runs

- Minimum stoppage time

- Assurance during client appraisals

- Operational trustworthiness fosters confidence over time.

Area Optimization & Facility Layout Advantages

Space is a genuine concern for many manufacturers. Small Indian workshops and high-cost premises in territories such as the UAE, the UK, and parts of Europe require compact, efficient arrangements.

A thoughtfully engineered rolling machine integrates seamlessly into existing production sequences with minimal structural changes, helpingenabling producers maximizeto maximize usable area without disrupting the workflow.

Long-Term Business Benefit for Global Jewellery Brands

The true worth of consistent rolling manifests over the extended term. Fewer rejected items, fewer remakes, and more consistent quality all strengthen customer relationships.

International purchasers value suppliers who deliver uniformity. Over time, this builds a firm reputation and repeat engagements—without focusing on fleeting cost discussions.

Export Grade, Adherence & International Norms

Export venues mandate documented consistency. Machine-based rolling supports:

- Level gauge across production lots

- Simpler adherence to buyer specifications

- Improved results during inspection checks

For manufacturers serving Europe or North America, this uniformity safeguards brand standing.

Fitting into the Current Jewellery Production Flow

The Jewellery Wire Sheet Rolling Machine integrates seamlessly into established procedures, whether the facility leans towards casting-intensive output or hand-finished items.

It pairs well with:

- Casting and forming activities

- Polishing and final treating lines

- Flexible production styles across various nations

This versatility makes it suitable for a wide range of manufacturing settings.

Instruction, Servicing & Worldwide Applicability

In multinational facilities, simplifying instruction is essential. Apparatuses requiring minimal learning periods help sustain output even amid workforce transitions.

Features promoting global utility include:

- Uncomplicated technician instruction

- Straightforward routine upkeep

- Extended operational lifespan across differing working conditions

These aspects lessen dependence on continuous technical involvement.

Why is Selecting the Appropriate Manufacturer Important?

Not all machines maintain performance over time. Opting for a producer with an international supply background ensures:

- Dependable post-sale assistance

- Accessibility of replacement components

- Grasp of global jewellery manufacturing requirements

This becomes particularly relevant for export-oriented units.

About HK Malvi Industries

HK Malvi Industries is a seasoned manufacturer of gold jewellery equipment serving both the Indian and global arenas. With a realistic understanding of workshop realities and export conditions, the organization emphasizes reliable machinery that supports consistent production across regions. Further insights are found at 👉 https://www.hkmalviindustries.com/

Summary:

Across global jewellery manufacturing sectors, the Jewellery Wire Sheet Rolling Machine has demonstrated itself to be a practical tool for achieving precision, reducing waste, and maintaining uniformity. From modest workshops to export-driven facilities, it meets contemporary production needs without undermining established craftsmanship. For producers prioritizing enduring excellence and client confidence, this equilibrium is key.

Main Conclusions

- Worldwide Productivity Enhancement

- Export-Grade Uniformity

- Diminished Gold Depletion

- Sustained Expense Effectiveness

- Increasing International Industry Acceptance

FAQs

1. Is a gold jewellery-making device suitable for smaller workshops?

- Yes, numerous devices are tailored for compact spaces and scalable output requirements.

2. How does machine rolling aid export caliber?

- It guarantees even thickness, boosting consistency and assessment outcomes.

3. Can a single device be utilized across varied gold fineness levels?

- Most rolling apparatuses are adaptable with appropriate procedural management.

4. Does operator skill remain relevant alongside machines?

- Yes, machines sustain uniformity, but knowledgeable assessment remains essential.

#GoldJewelleryMachinery #JewelleryManufacturing #ExportJewellery #JewelleryWireSheetRollingMachine #HKMalviIndustries #JewelleryMachines #MakeInIndiaForWorld #GlobalJewelleryIndustry