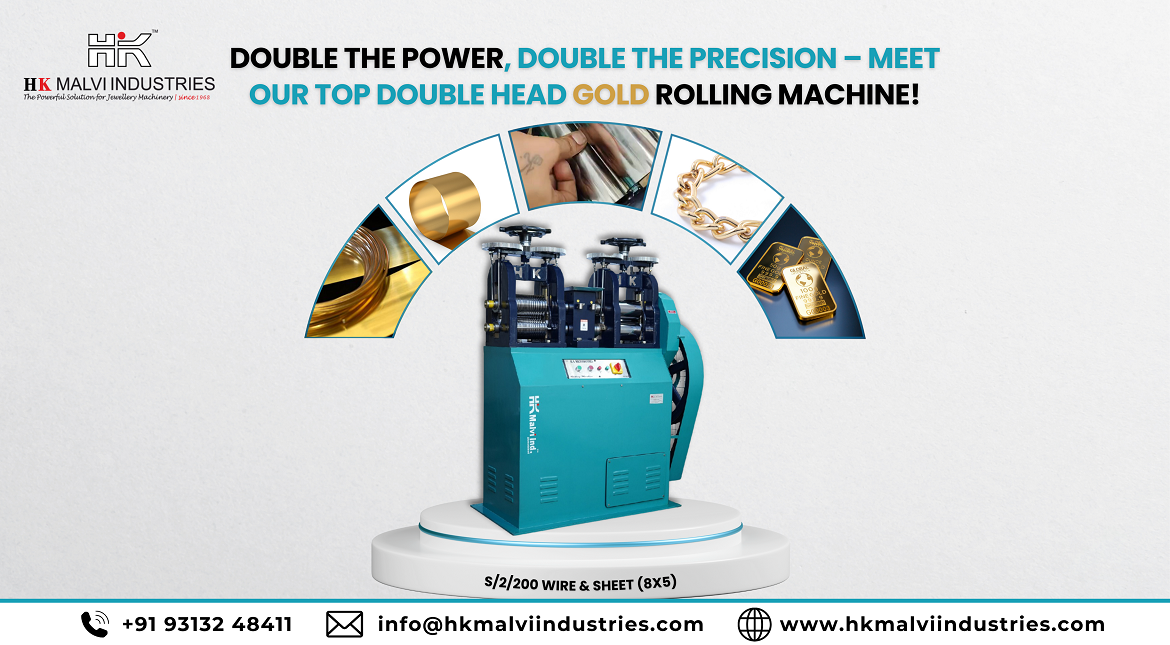

Elevate Your Craftsmanship with S/2/200 Wire & Sheet (8×5) Machines by HK Malvi Industries

When it comes to manufacturing premium Gold Jewellery Making Machines, HK Malvi Industries is a name synonymous with innovation, reliability, and precision. We take pride in offering top-grade machinery solutions, including the S/2/200 Wire & Sheet (8×5) Machines, engineered to meet the evolving needs of the jewellery manufacturing sector. As a premier Jewellery Machine Manufacturer in India, we specialize in crafting machines that blend technology and tradition.

HK Malvi Industries is a Manufacturer, Supplier, and Exporter of S/2/200 Wire & Sheet (8×5) Machines in Bihar.

Our Manufacturing Unit is in Ahmedabad, Gujarat, India.

HK Malvi Industries Are Manufacturer of Jewellery Wire & Sheet Rolling Machines including Machines Are Single Head Gold Rolling Machine, Top Double Head Gold Rolling Machine, Electric Jewellery Double Head Rolling Machine, Top Quality Double Head Gold Rolling Machine, Top Single Head Gold Rolling Machine, High-Quality Metal Touch Rolling Machines, Compact Machine, Top Gold Rolling Machine, Double Head Machine(Royal), Wire Drawing Machine, and Bull Block Wire Machine.

Features S/2/200 Wire & Sheet (8×5) Machines:

Our S/2/200 Wire & Sheet (8×5) Machine is engineered with cutting-edge features to meet the demanding requirements of modern jewellery production:

- Dual Head Design: This innovative feature allows for simultaneous rolling of both wires and sheets, significantly boosting productivity and reducing production time.

- High Precision Rollers: Crafted from hardened and ground alloy steel, the rollers ensure exceptional durability and deliver a consistently smooth, polished finish on your gold and precious metal materials.

- Robust Construction: The heavy-duty body minimizes vibrations during operation, leading to higher accuracy and a longer lifespan for the machine.

- User-Friendly Operation: Designed with ergonomics in mind, the machine features intuitive controls, making it easy for operators of all skill levels to achieve optimal results.

- Energy-Efficient Motor: Experience maximum output with reduced power consumption, leading to lower operational costs.

- Advanced Safety Mechanisms: Built-in safety features protect both the operator and the machine, preventing overloading and ensuring a secure working environment.

- Smooth Finishing: Achieve a pristine and polished finish on all your gold sheets and wires, essential for high-quality jewellery.

- Wide Range of Applications: Capable of handling gold, silver, platinum, copper, and other soft precious metals.

- Compact Footprint: Despite its powerful performance, the machine boasts a compact design, making it suitable for workshops with limited space.

Why Choose HK Malvi Industries for Your Jewellery Machines?

When it comes to investing in gold jewellery making machines and other essential equipment, HK Malvi Industries stands out as a name synonymous with quality, innovation, and customer satisfaction.

- Decades of Expertise: With years of experience as a prominent Jewellery Machine Manufacturer, we possess deep industry knowledge and understand the unique challenges and requirements of jewellers.

- Uncompromising Quality: We adhere to stringent quality control measures, using high-grade materials and precision engineering to manufacture machines that are built to last and deliver exceptional performance.

- Innovative Technology: We constantly integrate the latest technological advancements into our machines, ensuring you have access to cutting-edge solutions that enhance efficiency and accuracy.

- Customized Solutions: We understand that every workshop has unique needs. We offer customization options to tailor our machines to your specific production requirements.

- Reliable After-Sales Support: Our commitment to our customers extends beyond the sale. We provide comprehensive after-sales service, including installation guidance, maintenance tips, and prompt technical support.

- Pan-India Presence: As a leading Jewellery Machine Manufacturer in India, we cater to a vast customer base across the country, ensuring accessibility and timely service.

- Trusted Reputation: Our long list of satisfied clients and positive testimonials speak volumes about our dedication to excellence and customer trust.

Benefits of Using S/2/200 Wire & Sheet (8×5) Machines:

- Enhanced Productivity: The dual-head design and high-speed rolling capabilities significantly increase your output, allowing you to meet higher production demands and deliver orders faster.

- Superior Quality Output: Produce high-precision sheets and wires with a flawless finish, crucial for crafting intricate and luxurious jewellery designs.

- Reduced Operational Costs: Energy-efficient motors and durable construction lead to lower power consumption and minimal maintenance, saving you money in the long run.

- Increased Accuracy and Consistency: Minimize errors and ensure uniform thickness and dimensions for all your rolled materials, leading to less wastage and higher product quality.

- Versatile Production: The ability to handle various precious metals and produce both wires and sheets makes this machine a versatile asset for any jewellery workshop.

- Long-Term Reliability: Our robust machines are designed for continuous operation, offering dependable performance and a strong return on your investment.

Machine Descriptions:

- 5 Hp Three Phase Electric Motor

- Flywheel System

- Roller Metal- D2

- Safty Guard – Optional

- Standard Control Pannel

- Branded Electrical Fittings

- Standard Accessories

- Heavy Duty Fabrication Structure

- Machine Dimension- 1200x480x1190 MM

- Machine Weight- 790 KG

Machine Specifications:

- Sheet Size Inlet to Outlet- 15-0.2MM

- Wire Size Inlet to Outlet- 16-0.7MM

- No Noise & No Vibration

- High Productivity

- Warranty- 01 YEAR

Applications:

- Gold Sheet Manufacturing

- Gold Wire Drawing

- Jewellery Prototyping

- Mass Production Workshops

- Custom Design Studios

- Pattern Imprinting

- Ring Sizing and Shaping

Frequently Asked Questions (FAQs)

1. What materials can be processed in S/2/200 Wire & Sheet (8×5) Machines?

- The machine is best suited for processing gold, silver, and other precious metals commonly used in jewellery making.

2. Can I use the machine for large-scale production?

- Absolutely. The machine is designed to support both small workshops and large production units with ease.

3. Do you provide after-sales support in Bihar?

- Yes, HK Malvi Industries offers comprehensive after-sales services including training, maintenance, and spare parts across Bihar and other regions.

4. How long does delivery take after placing an order?

- Generally, machines are delivered within 10–15 working days, depending on customization and location.

5. What is the warranty on the S/2/200 Wire & Sheet (8×5) Machine?

- We provide a standard 1-year warranty covering manufacturing defects and offer extended warranty packages as well.

HK Malvi Industries is Supplier of S/2/200 Wire & Sheet (8×5) Machines in Bihar including locations Patna, Gaya, Muzaffarpur, Darbhanga, Bhagalpur, Katihar, Purnia, Buxar, Bettiah, Chapra, Bihar Sharif, Siwan, Arrah, Sasaram, Begusarai, Munger, Saharsa, Kasba, Habibpur, Nalanda, Danapur, Nawada, Sitamarhi, Madhubani, Jamui, Bagaha, Kishanganj, Madhubani.

HK Malvi Industries an Exporter of Jewellery Wire & Sheet Rolling Machines of S/2/200 Wire & Sheet (8×5) Machines in Peru including locations Huánuco, Lima, Huancavelica, Tumbes, Pisco, Sechura, Paita, and Lambayeque.

Contact HK Malvi Industries now for S/2/200 Wire & Sheet (8x5) Machines—Bihar’s trusted name in machinery excellence.